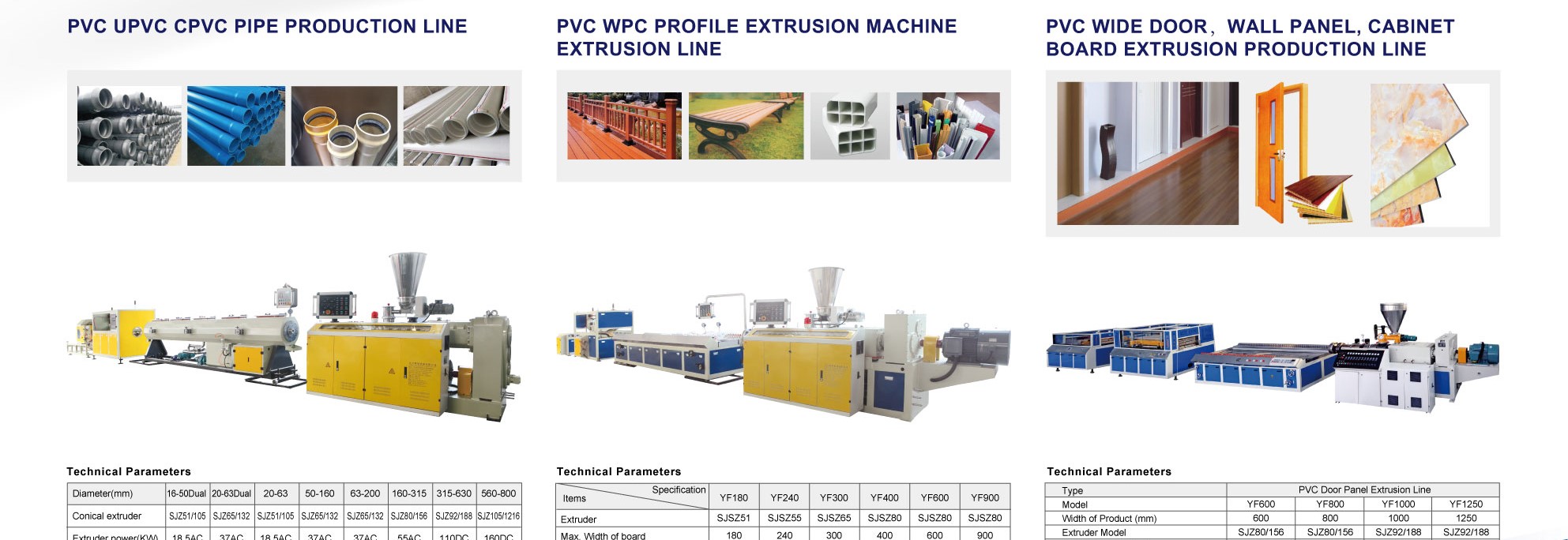

UPVC-HDPE Pipe Extrusion Machine

The PVC pipes produced by the PVC water pipe extrusion machine are widely used in municipal water supply and drainage, industrial water supply and drainage, civil water supply and drainage, irrigation, vegetation watering, etc. According to the diameter and function of PVC pipe, in the field of construction, PVC pipe is used for PVC conduit, PVC water supply pipe, PVC drain pipe, etc

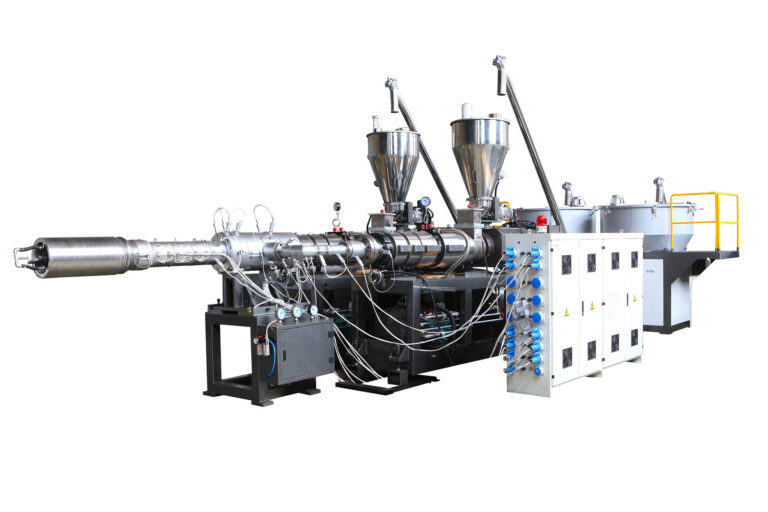

1. Conical twin screw extruder

The heart of the PVC pipe production process, extrusion machinery, consists of an extruder that melts and conveys the PVC resin through a die, shaping it into the desired pipe profile. The controls are from SIEMENS PLC and inverters of ABB.

2. PVC drain pipe mold

The mold is responsible for shaping the molten PVC material into the specific pipe profile. It determines the size and dimensions of the pipe.

Specifications: 75mm,80mm,90mm,100mm,110mm,125mm,140mm,160mm,200mm,250mm

3. Vacuum Calibration and cooling tank

With siemens, schneider sealing IP65,

Calibration Tank: The calibration tank is a critical component of the extrusion process for PVC pipes. It is designed to provide precise shaping and cooling to the newly extruded PVC pipe.

Cooling Water: The tank is filled with a controlled flow of cooling water. This water serves a dual purpose: it cools the hot PVC material and maintains the desired shape and dimensions of the pipe.

Vacuum System: The vacuum calibration tank features a vacuum system that assists in maintaining the shape of the PVC pipe. The vacuum removes air between the extruded pipe and the inner surface of the tank, helping to draw the PVC material against the walls of the tank and maintain the desired pipe profile.

4. Haul off and cutter

Haul off

Rubber piece type: V Rubber block

Model control: SIEMENS PLC

Cutter

Cutting pattern: ring form cutting

Clamp form when cutting: Pneumatic