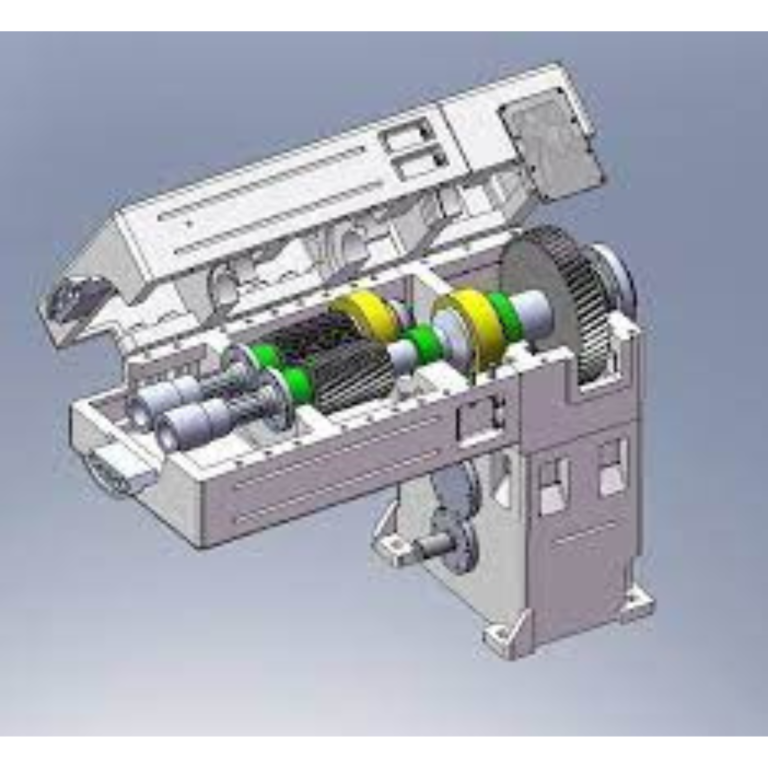

Gear Box

Vertical and Horizontal gearboxes refer to the orientation and arrangement of the gearboxes used to drive the screws in an extruder. These gearboxes play a crucial role in controlling the rotation of the extruder screw, which, in turn, processes and pushes the material through the extrusion process.

The gears are made of high strength alloy steel. The gear goes through the process of carburizing, quenching heat hardening and gear grinding to achieve the precision of grade 6, tooth surface hardness HRC54-62. The material of the box is made of high quality ductile iron. After casting, full stress treatment is carried out with high strength and beautiful appearance. All oil seals are imported, and the high speed shaft is treated with oil seal and mechanical seal, and the oil leakage rate is low

Gearbox can be used in PVC double pipe production lines for producing PVC conduit pipe, diameter from 16mm to 40mm, 16mm to 63mm, PVC sheet, profile, and wire and cable coating lines.

we have all conical sizes gear box 51/105, 55/120, 65/132, 80/156 available in stock at vatva, Ahmedabad.

Vertical gear box

Orientation: In a vertical gearbox, the gearbox is positioned vertically, meaning it is aligned in a way that the input and output shafts are arranged vertically, one above the other.

Advantages: Vertical gearboxes can be more compact and space-efficient in some setups. They are suitable for applications where the extruder needs to process materials vertically, such as in the production of certain profiles, pipes, or cables

Horizontal gear box

Orientation: In a horizontal gearbox, the gearbox is positioned horizontally, meaning the input and output shafts are aligned parallel to the ground.

Advantages: Horizontal gearboxes are well-suited for applications that require a horizontal screw arrangement. They are often used in extrusion processes where gravity or material flow considerations favor a horizontal configuration.